2021-11-30 1 Wash, filter and grind the granite ore with into smaller pieces. 2 Put the ground ore into a tank containing a dilute cyanide solution and add zinc. The chemical reaction between a dilute cyanide solution and zinc will separate the gold from the ore. 3 Use a filter press to remove the gold from the solution.

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation.This completely updated edition features coverage of established, newly

The process may be continued until the gold content is >99.5%, when it is cast into bars or into anodes for further electrolytic refining. Materials almost free of platinum group metals are treated by the Wohlwill electrolytic process, which is widely used in major gold refineries, often in combination with the Miller process.

2015-9-15 This page offers a comparative review of gold recovery methods: Flotation and Leaching of the Float Conc. Flotation and Leaching of the sulfide

2017-9-7 Gold/silver base metal concentrate deportment. Smelters typically pay >95% (Au) and 90% (Ag) in copper and lead concentrates, but will only pay 60-70% (maximum, depending on degree of Pb/Zn smelter integration) for gold and silver in zinc concentrates. Cost drivers are also important in flowsheet selection, and are summarised in Table 3.

The gold extraction rate for raw gold ore under optimum conditions (0.25 M potassium bromate, 0.08 M ferric chloride, 0.4 M hydrochloric acid, extraction time of 5 min, stirring speed of 250 rpm, and liquid-to-solid ratio of 5) was 94.5%. For a gold flotation concentrate, the gold extraction rate was as high as 91.8%.

1991-1-1 The Mereur ore as well as containing Processing of refractory gold ores 1033 carbon has a significant carbonate content and this allows the process to be operated in the alkaline pH range. First Miss Gold Inc. Getchell project achieved commercial production during 1989.

2019-11-9 2, Mud removal and disintegration. After the initial screening, the influence of large gravel on the gold selection process has been removed. The second process is desludging and disintegration. Desludge and disintegration actually doing the same job, that is, by sand-washing, mechanical scrubbing and other progress, the gold and mud in the

2016-2-28 Intensive cyanidation is a good option, but obviously, the material can be sent to the leaching process employed to treat the raw ore. Gold and silver recoveries are between 99.5 to 99.7%. Although slag production weight is variable, a typical operation can generate 10 kilos of slag per 1000 oz of gold.

2017-9-6 Mineralogy and Occurrence of Gold: The term “carbonaceous” has been loosely applied to ore constituents of widely varying characteristics. Laboratory investigations by A. S. Radtke and B, J. Scheiner (1970) of the U. S. Geological Survey and the U. S. Bureau of Mines on carbonaceous ores from Carlin showed that they contained: (1) an

2016-2-29 The main problem is to use very opened sisal clothes than can work properly for coarse gold, but it is unlikely efficient for medium and fine gold particles. This material costs around US$ 4/m2. It is matter of trying different

2016-7-14 Roasting and Processing Sulpho-telluride ore to recover gold. This roasting plant, since closed down, was equipped with eight standard 70-spindle Edwards roasters, though only four were finally in use. Fuel was supplied to four

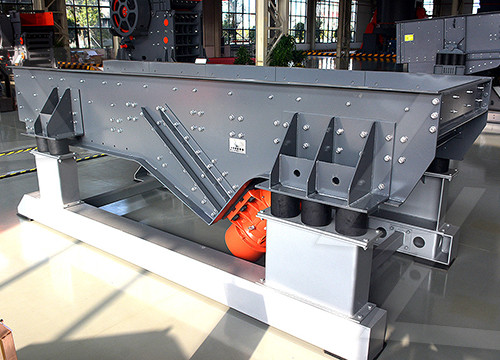

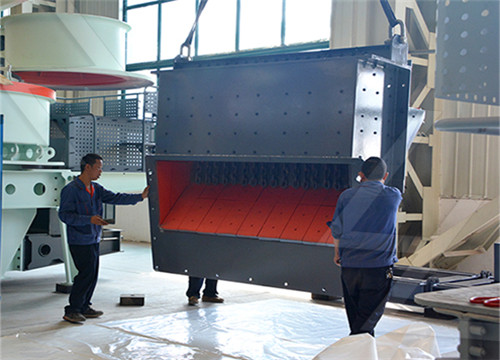

2019-6-28 Comminution is the process where ore particles are liberated from gangue material through progressive size reduction in the form of crushing, grinding, cutting or vibrating. The costs associated with power supply, grinding

Gold, recognizable by its yellowish cast, is one of the oldest metals used by humans. As far back as the Neolithic period, humans have collected gold from stream beds, and the actual mining of gold can be traced as far back as 3500

2021-10-13 Study shows new chloride-based process recovers 84% of gold compared to the 64% recovered with traditional methods. Gold is one of the world’s most popular metals. Malleable, conductive and non-corrosive, it’s used in jewelry, electronics, and even space exploration. But traditional gold production typically involves a famous toxin, cyanide

A solvent extraction method using diisobutyle ketone (DIBK) is designed for the accurate and precise estimation of very low concentrations of gold in rocks, ores and other geological samples. 30 g

Obtained by processing: Unprocessed Sandstone Ore. more details Unprocessed Iron Ore. Unprocessed Material. Weight: 3. Mining Lv. Min: 40. Bring

2016-6-6 Sulfide sulfur oxidation through the autoclave is typically of the order of 90—92%. Residual S exiting the autoclave is targeted at less than 0.2%. Values greater than 0.25% S“ typically result in poorer gold recoveries in the C1L

2020-7-6 In the last 30 years, a great deal of effort has also been made to develop alternative technologies to process high-arsenic-containing materials. Focus has been on: Developing niche technologies for processing specific ore

2022-5-21 Ingredients. Crafting Recipe. 1 Respective Crushed Ore +. 75% chance additional Crushed Ore +. 75% chance Nugget of Experience +. 12% chance Cobblestone. Any Ore. 5. nil.

2017-1-18 1. Gold Processing. The first step in gold smelting involves processing the gold ore. The ore containing gold once mined from the earth is processed by separating gold minerals from the crude matter holding the ore

2022-1-12 In many countries, elemental mercury is used in artisanal and small-scale gold mining. Mercury is mixed with gold-containing materials, forming a mercury-gold amalgam which is then heated, vaporizing the mercury to obtain the gold. This process can be very dangerous and lead to significant mercury exposure and health risks.

Gold leaf. The Egyptians believed gold to be a divine material which held magical powers. Electrum is an alloy of gold which is approximately 80% gold mixed with 20% silver. An alloy is a mixture of metals or a mixture of a metal with small

2022-5-12 Gold Ore is a naturally occurring rare ore found in deep veins on planets, moons, and asteroids. It has a shiny metallic yellowish appearance. Gold is used to make late-game components such as Gravity Components,

2007-4-26 Abstract. Abstract. The processing of gold bearing sulphide minerals which contain arsenopyrite and other complex arsenic sulphide minerals results in arsenic containing emissions and effluents which must be given careful consideration in relation to clean air and clean water standards. The sources of arsenic and the various process options for

2021-10-13 Study shows new chloride-based process recovers 84% of gold compared to the 64% recovered with traditional methods. Gold is one of the world’s most popular metals. Malleable, conductive and non-corrosive, it’s used in jewelry, electronics, and even space exploration. But traditional gold production typically involves a famous toxin, cyanide

A solvent extraction method using diisobutyle ketone (DIBK) is designed for the accurate and precise estimation of very low concentrations of gold in rocks, ores and other geological samples. 30 g

materials processing, series of operations that transform industrial materials from a raw-material state into finished parts or products. Industrial materials are defined as those used in the manufacture of “hard” goods, such as more or less durable machines and equipment produced for industry and consumers, as contrasted with disposable “soft” goods, such as chemicals,