2019-10-8 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size meet the selection

Crushing and grinding machine for mining industry in. Grinding is distinct from crushing operation; it is the process of reducing materials to a powder of fine or very fine size, which involves size reduction to a rock, pebble or grain size.Material grinding is an integral step in industrial processing applications.In mineral grinding systems, the mineral from crushing and screening

2010-7-1 Crushing and grinding processes have undergone significant changes over the last 20 years.These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly

Crushinggrinding solutions. Crushing is a crucial process in the mineral industry, so reliability of the products for these applications must be extremely high to ensure process continuity. Bonfiglioli solutions for crushers are extremely robust and manufactured to the highest quality criteria. Our heavy-duty products for these applications

2015-7-18 Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or coarser; intermediate crushing comprises operations taking feeds 6- or 8-in. maximum and making products down to -1/2″ or 3/8″. Fine crushing is reduction by crushing to 1/4″ or finer; the distinctions are not sharp.

Crushing is usually a dry process, while milling is performed with water. The advantage of wet milling is the lower energy input compared to dry milling. Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the

2019-8-30 A reasonable grinding-classification process is mainly determined by the following factors: 1. Disseminated grain size and common characteristics of useful minerals and gangue minerals; 2. The hardness and density of useful ore and gangue minerals; 3. The argillization degree and oxidation of useful ore and gangue minerals;

2015-12-26 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate

2020-4-20 Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses. Also, crushin processing is widely used in waste and recycling, mining,

2018-3-8 Grinding, crushing. Grinding (milling) is used for the size reduction of solid dry material. This process is necessary to facilitate the yeasts’ multiplication and also to conduct traditional macerations before pressing. Field of application. Grinding/milling is applied in sectors in the industry where dry solid materials are

2019-10-8 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size meet the selection

2016-9-9 Sep 9, 2016. |. The purpose of crushing and grinding is to reduce the size of the potential ore particles to that where there is sufficient REE mineral liberation and the size/size distribution is suitable for the chosen downstream

2015-7-18 Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or coarser; intermediate crushing comprises operations taking feeds 6- or 8-in. maximum and making products down to -1/2″ or 3/8″. Fine crushing is reduction by crushing to 1/4″ or finer; the distinctions are not sharp.

Crushing is usually a dry process, while milling is performed with water. The advantage of wet milling is the lower energy input compared to dry milling. Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the

2020-7-2 With the help of grinding equipments, extraction of metals from rocks have become easier, thus improving and simplifying the mining process. Adoption of grinding and crushing equipments in mining helps in increasing work productivity due to reducing particulate size of extracted materials more efficiently than earlier.

2021-5-18 Quartz Exploitation Crushing Plant in Sweden. The first part of the crushing process is that quartz stone normally is delivered to the feeder and taken to the crusher uniform and continuous. After thecrushing process, quartz is turned to power which is normally 7.5 to 30 centimeters in diameter.

2021-7-14 Limestone Grinding Process Limestone Mining Process. Limestone grinding process be divided into open circuit process and closed-circuit process The two mining process can meet different fineness requirements. Limestone is the main raw material for the production of cement concrete coarse and fine aggregate lime etc. Flow Chart Of Mining Process

2022-5-19 Frequent problems in crushing, screening, grinding and beneficiation process of mining plant 2022-05-19 Summary: At present, the commonly used mineral processing equipment in mineral processing plants include crushing equipment, grinding equipment, screening equipment, magnetic separation equipment, and flotation equipment.

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. 70% increase in the required feed for grinding with optimized crusher liners. of our worth is in the results we deliver to our customers. 100+ years of experience in delivering high-capacity crushing solutions for the mining industry

2022-1-23 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

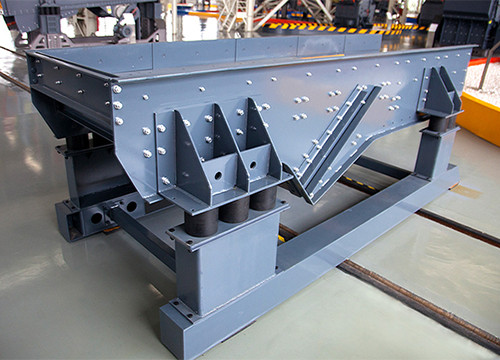

2022-5-11 The FIT Station to be delivered to Posse has a design capacity of 540 t/h of run of mine with an average production of 102,000 oz/y of gold (years 1 to 4). The station consists of crushers, vibrating feeders and screens, as well as conveyors and related structures and other equipment. Amarillo Gold is advancing two gold projects in Brazil.

2020-9-7 In quarry or mining industry, crushing and grinding are usually used for making stones or rocks into smaller size or even powder size. However, there are lots differences between crushing and grinding, and each progress need different machines. The progress of processing large stones or rocks into smaller size (mainly granularity size) is

Crushing is usually a dry process, while milling is performed with water. The advantage of wet milling is the lower energy input compared to dry milling. Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the

2019-8-30 A reasonable grinding-classification process is mainly determined by the following factors: 1. Disseminated grain size and common characteristics of useful minerals and gangue minerals; 2. The hardness and density of useful ore and gangue minerals; 3. The argillization degree and oxidation of useful ore and gangue minerals;

2022-5-19 Frequent problems in crushing, screening, grinding and beneficiation process of mining plant 2022-05-19 Summary: At present, the commonly used mineral processing equipment in mineral processing plants include crushing equipment, grinding equipment, screening equipment, magnetic separation equipment, and flotation equipment.

2021-7-14 Limestone Grinding Process Limestone Mining Process. Limestone grinding process be divided into open circuit process and closed-circuit process The two mining process can meet different fineness requirements. Limestone is the main raw material for the production of cement concrete coarse and fine aggregate lime etc. Flow Chart Of Mining Process

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. 70% increase in the required feed for grinding with optimized crusher liners. of our worth is in the results we deliver to our customers. 100+ years of experience in delivering high-capacity crushing solutions for the mining industry

In the limestone assembly process, we will mainly acquaint to you limestone crushing action and limestone grinding system. –grinding mill,limestone grinding plant,grinding Shanghai the Joyal Mining Machinery Co., Ltd. is a professional of a crusher manufacturer, described in this web site is: grinding appliction, grinding plant

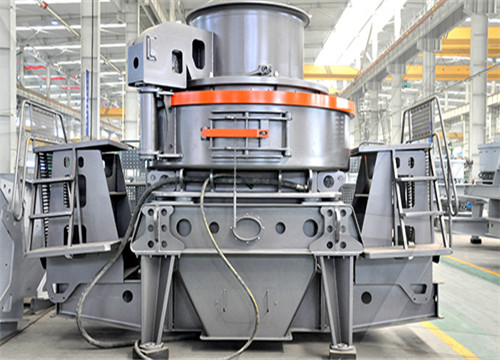

MCZB is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling.

2022-5-13 There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4