2013-3-12 Iron Ore Secondary Crushing Equipment. kefid Group is a professional mining machinery manufacturer. secondary crushing Mining Solution. Secondary Crusher,Secondary Crushing Plant,Clay Seconary Crusher in kefid is suitable for most of minerals such as Clay. Secondary Crusher Machines are advantaged

2021-11-20 Iron ore is main raw material of steel enterprise. Natural iron ore is processed to iron by crushing, grinding, magnetic separation, flotation, etc. processes. Iron is widely used in infrastructure and daily life. Iron ore can be

2022-4-23 The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB). Iron Ore Crushing Plant. Technological Process of iron ore crushing plant is: Iron ore----- transported by the dump truck ----- Vibrating feeder ----- Jaw crusher (Primary crusher) ----- Spring cone crusher (Secondary crusher) ----- Circular

2015-1-1 Iron ore crushing and screening. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. OPTION 3: Primary crushing—closed

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and

2018-3-14 Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling. This step involves breaking up the iron ore to obtain an

2016-2-28 The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater

Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency January 2019 E3S Web of

2015-12-26 After the mine has blasted the ore, the first reason why we crush rock is really to be able to transport it onto the next same. Secondary: Cone/HPGR. 6″-18″ (150-450mm) 1 1/4″

2022-4-23 The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB). Iron Ore Crushing Plant. Technological Process of iron ore crushing plant is: Iron ore----- transported by the dump truck ----- Vibrating feeder ----- Jaw crusher (Primary crusher) ----- Spring cone crusher (Secondary crusher) ----- Circular

2022-4-22 1.Crushing and sieving. Large iron ore is sent to the jaw crusher or mobile jaw crusher for coarse crushing by the vibrating feeder. The coarsely-crushed iron ore is sieved by the vibrating screen and sent by the belt conveyor and secondary crushed by single-cylinder hydraulic cone crusher; the crushed iron ore material is fed into HP Series

Solar Panel and Battery Box Support Frames, SA. Location: Iron Baron South Australia. Industry: Mining. Fully designed, constructed, and installation of Iron Ore Crushing plant (SecondaryTertiary sections) Design of plant to produce 1200 TPH of Iron Ore. EngineeringDesign of the complete Screen Structure 6 off Screens.

2018-3-14 Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling. This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process

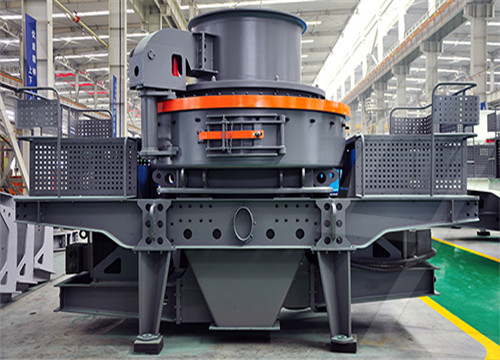

2021-6-30 Impact crusher is generally used as a secondary crushing equipment. It can process materials with a side length of less than 1300 mm. Its compressive strength can be as high as 350 MPa. iron ore crushing plant in malaysia iron ore crusher, gold ore . Iron ore processing plant works not only the iron ore, such as dry and wet

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater than 60% iron is known as natural ore or direct shipping ore, meaning it can be fed directly into iron-making blast furnaces.

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method. The main objective of the primary beneficiation plant is the crushing of the ROM from the

2009-6-5 –Process 600t/h lumpy iron ore • DMS Cyclone –Only -6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –-90+6mm stones –1.2m diameter –Operating capacity of 600-800t/h –Efficient separation at SG’s as high as 4.1g/cm3 Dense Media Separation on Iron Ore •

2018-3-27 The crushing units may include primary, secondary, t artery and quaternary crushing systems. Jaw, gyrator, cone, and roll crushers are used for ore crushing. Semi toughens grinding and AU toughens grinding circuits are used for grinding the ore. Size fraction of the iron ore used for gig Eng is 0. 5 mm to mm. Http://asparagus. Com

An option study for a 10 Mt/a ore processing plant for a. consistently hard, fine-grained silica-rich magnetite ore was. carried out, with the emphasis on comminution circuit options. A. capacity

2022-4-22 1.Crushing and sieving. Large iron ore is sent to the jaw crusher or mobile jaw crusher for coarse crushing by the vibrating feeder. The coarsely-crushed iron ore is sieved by the vibrating screen and sent by the belt conveyor and secondary crushed by single-cylinder hydraulic cone crusher; the crushed iron ore material is fed into HP Series

2022-5-12 Iron Ore Crushing Production Line,ore crushing line,iron crushing line,Iron Ore CrushingProcessing +8613676922906. Email:sales@zxcrusher. Through primary crushing, and then by

Solar Panel and Battery Box Support Frames, SA. Location: Iron Baron South Australia. Industry: Mining. Fully designed, constructed, and installation of Iron Ore Crushing plant (SecondaryTertiary sections) Design of plant to produce 1200 TPH of Iron Ore. EngineeringDesign of the complete Screen Structure 6 off Screens.

2021-6-30 Impact crusher is generally used as a secondary crushing equipment. It can process materials with a side length of less than 1300 mm. Its compressive strength can be as high as 350 MPa. iron ore crushing plant in malaysia iron ore crusher, gold ore . Iron ore processing plant works not only the iron ore, such as dry and wet

2018-3-14 Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling. This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground.

2021-12-2 Mobile Multi-Stage Crushing: EQUIPMENT USED: Mobile Jaw Crusher (Primary) Finlay J-1480 Mobile Cone Crusher (Secondary) Finlay 984 Horizontal Screen Mobile Screen (Secondary) Metso St4.8: ROCK TYPE: Iron Ore: FINAL PRODUCT:-32mm: Volume: 120 000 tpm: Related Projects. Crushing. MINERAL PROCESSING MANGANESE . Iron Ore.

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig. 13.45).Iron ore requires removal of silicate impurities of a finer size by flotation for higher-grade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm.

Ore processing operations at Newmont Boddington Gold . The process flow sheet at Newmont Boddington Gold NBG comprises primary crushing closed circuit secondary and tertiary crushing using High Pressure Grinding Rolls HPGR ball milling and hydro cyclone classification to generate a milled product with a P 80 of 150 µm The ground ore is then floated to produce a gold rich

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater than 60% iron is known as natural ore or direct shipping ore, meaning it can be fed directly into iron-making blast furnaces.

2018-3-27 The crushing units may include primary, secondary, t artery and quaternary crushing systems. Jaw, gyrator, cone, and roll crushers are used for ore crushing. Semi toughens grinding and AU toughens grinding circuits are used for grinding the ore. Size fraction of the iron ore used for gig Eng is 0. 5 mm to mm. Http://asparagus. Com