The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84-inch-long (213 cm) roll crushing to pass 10 inches (25 cm).

2021-8-25 Toothed roll crusher is mainly for splitting and grinding, which is suitable for coarse and medium crushing of brittle and soft ores. The specification of the roll crusher is expressed by the roll diameter D x length L. The parameters of the roller crusher series produced by Henan Deya Machinery Co., Ltd. Roll crusher series technical parameters

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site testing.

2017-12-12 The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap. increases, quality or broken down, so as to

2022-5-13 The Handling Materials of Roller crusher Our roll crushers can be used for primary and secondary crushing of mineral coal clay marl limestone and similar raw materials as well as for overburden and are simple in design and construction longlasting economical and roll crusher is driven by the driving chain of the speed reducer. .

The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries . Williams is an industry-leading roll crusher manufacturer and designer for high-quality roll crushers with desirable benefits such as high throughput

HRC Roll Crusher. For the industrial beneficiation of primary and secondary raw materials, crushing procedures for the production of certain grain sizes, forms, surfaces or for the outcrop of multi-component materials play a central role. The utilised crusher must meet stringent requirements of today’s time when processing rocks, ores and coals.

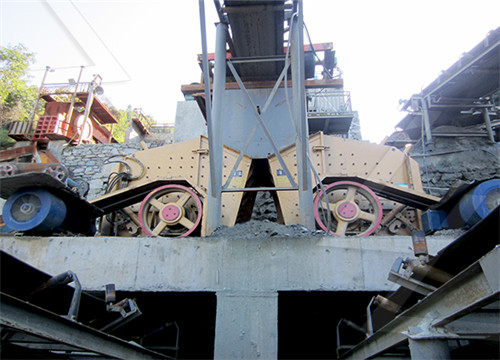

2018-9-12 Double roll crusher (also called twin roll crusher) is composed of two cylindrical rollers as the main working mechanism (Figure 1). When working, the two round rollers rotate in opposite directions, and the material (ore) is crushed by the friction between the rollers, which rolls the material into the crushing cavity formed by the two rollers.

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1. The simplified design gives these units excellent reliability and requires very little maintenance. The crushers are designed with built-in tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the

2022-5-13 The Handling Materials of Roller crusher Our roll crushers can be used for primary and secondary crushing of mineral coal clay marl limestone and similar raw materials as well as for overburden and are simple in design and construction longlasting economical and roll crusher is driven by the driving chain of the speed reducer. .

Roller crusher. The roller crushers are designed for crushing, crumbling, and premixing of big hard and shale type clay clods, up to a hardness of 5–6 Mohs. Such actions are carried out by two toothed rollers with parallel axis, rotating opposite directions with differential speeds. These toothed rollers crush the material forcing it to pass

HRC Roll Crusher. For the industrial beneficiation of primary and secondary raw materials, crushing procedures for the production of certain grain sizes, forms, surfaces or for the outcrop of multi-component materials play a central role. The utilised crusher must meet stringent requirements of today’s time when processing rocks, ores and coals.

2018-9-12 Double roll crusher (also called twin roll crusher) is composed of two cylindrical rollers as the main working mechanism (Figure 1). When working, the two round rollers rotate in opposite directions, and the material (ore) is crushed by the friction between the rollers, which rolls the material into the crushing cavity formed by the two rollers.

Teeth roller coal crusher principle is: the fuel enter from up, and discharge directly from bottom outlet, without secondary crushing. To achieve the crushing purpose through crushing and screening by snap action between teeth, the grain evenly, over powder rate is very low, and its broken particle size can be quickly adjusted by the screw, to fully meet the requirements of

2022-5-2 The toothed roller crusher is a crusher specially designed for CFB power plants. It is especially suitable for crushing coal gangue, lignite, bituminous coal and peat. and the vibrating spring of the circular vibrating screen also has an important auxiliary role. The following briefly introduces the types of circular vibrating screen

Double-roll crushers crusher is a commonly used roller crusher, and its crushing mechanism is a pair of cylindrical rollers horizontally mounted horizontally on the frame. Therefore, crushing is continuous operation, with the role of forced unloading. Roll crusher main technical parameters . Model. 2PG400×250. 2PG610×400. 2PGC450×500

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary

2022-5-21 The roller crusher with saw teeth on the surface of both rollers mainly plays the role of cracking and tearing, and also has the role of crushing, grinding and crushing. The broken teeth arranges in a spiral shape. The small particles in the feed are easily discharged through the gap between the broken rollers.

2021-8-11 ROLE_是默认的一个缀,可以覆盖,但是不建议为空,这点我在👉官方文档中也查询到了。因为如果为空的话,空的角色缀意味着投票者将为每个 ConfigAttribute 投票。就是每个都可以通过的意思(自我理解)。

2022-5-13 The Handling Materials of Roller crusher Our roll crushers can be used for primary and secondary crushing of mineral coal clay marl limestone and similar raw materials as well as for overburden and are simple in design and construction longlasting economical and roll crusher is driven by the driving chain of the speed reducer. .

2022-5-2 The toothed roller crusher is a crusher specially designed for CFB power plants. It is especially suitable for crushing coal gangue, lignite, bituminous coal and peat. and the vibrating spring of the circular vibrating screen also has an important auxiliary role. The following briefly introduces the types of circular vibrating screen

The global roller crusher market expanded significantly in 2018. This trend is expected to continue during the forecast period. urbanization is fuelling the roller crusher market across the globe. Asia Pacific accounts for large share of the roller crusher market. It is also a rapidly growing region of the market.

The roller crusher will crush the crushed material through the feeding mouth into the two rollers, After being squeezed and crushed, the finished material falls naturally. When there are too hard or can not be broken, the roller in hydraulic cylinder or spring under the role of automatic retreat, so that the gap between the roller increased

Roller crusher is a very old crushing equipment that appeared in 1806, and its structure is simple. It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, K-albite, limestone, river pebbles, copper ore, bauxite, barite, basalt, etc The role of impact

SP50 Gyratory Crusher Increased capacity, with reduced maintenance and downtime is what the SP50 Secondary Gyratory Crusher delivers. The SP50 features tramp iron relief via accumulator and relief valve, adjustable stroke, roller bearing eccentric mechanism, a spherical plain spider bearing, removable spider arm, a constant feed opening crushing chamber and a large

1 KHD Humboldt Wedag Roller Presses offer rollers with appropriate wear protection for almost all applications in the cement and minerals industry. The two-part roller consisting of shaft and tire allows for economical surface

2019-3-28 March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who

This is stat roller. It is an online resource for rolling stats for DND / d&d 5e. I was tired of convoluted websites to roll stats for my dnd / d&d characters and decided to make a very simple one for users to find and not have to think about specifics of everything. Many people use dnd beyond these days, so this is a tribute to those who still

2022-3-23 Model NO.: 2PG400*500 Type: Roll Crusher Motor Type: AC Motor Motor Power: 22kw Application: Coal Metallurgy Mine Chemical Industry Et Materials: Coal