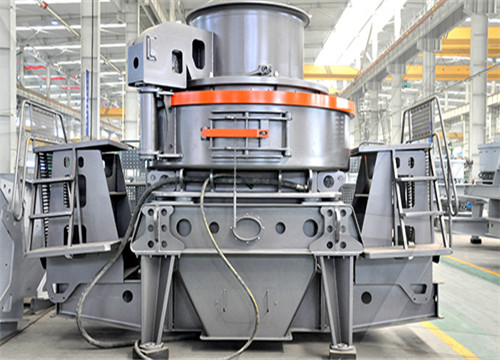

Its feed size is 125mm~1020mm, and the single machine output is as high as 600TPH. It is an ideal choice for primary crushing equipment. The GP (single-cylinder) hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines. Eastman single-cylinder hydraulic cone crusher

2022-4-25 There are more than 200 kinds of copper-bearing ores in nature, and common copper ores can be divided into three types: natural copper, sulfide ore and oxide ore. The gangue of copper ore is mainly quartz, followed by calcite, feldspar, mica, chlorite, barite, etc. SANME, as a famous supplier of mining crushing solutions, can offer complete set

2022-4-25 Screens size and distribute the classified ore to a series of conveyors, like those above, for transportation to the mill for further processing. 03. After crushing process, the copper ore is send to ball mill for grinding. Inside the ball mill, the crushed copper ore will grind the ore to about 0.2 mm with 3-inch steel balls. 04

2021-5-18 Copper Ore Crushing Production Line, Mobile Crusher Machine for Processing. Crushing is the first stage in copper production operation; it aims to reduce the large lumps of

2022-2-22 The high copper prices of recent years are producing a substantial supply response. Copper ore a valuable mineral source for all countries. The biggest copper mines are in Chile

2012-10-18 Copper Ore Crushing and Grinding Process. First the copper ore is blasted, the copper ore stone will be loaded by way of a durable truck, then be transported to the primary

The copper ore crushing and sorting process mainly includes four processes: copper ore crushing, grinding, beneficiation and copper fine powder drying. In the copper ore crushing

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required. Prominer has the ability to supply complete crushing and screening system, including various

2016-7-12 Common Crushing Plant DesignLayout. New Crushing Technologies. Methods used in CrushingScreening Plants on ore range from a simple combination of a grizzly and

2022-4-25 Mobile Crushing Station mainly include crawler and wheeled-type crushers. This selection include jaw crushers, impact crushers, cone crushers and screens. Mobile Screening

2022-4-25 There are more than 200 kinds of copper-bearing ores in nature, and common copper ores can be divided into three types: natural copper, sulfide ore and oxide ore. The gangue of copper ore is mainly quartz, followed by calcite, feldspar, mica, chlorite, barite, etc. SANME, as a famous supplier of mining crushing solutions, can offer complete set

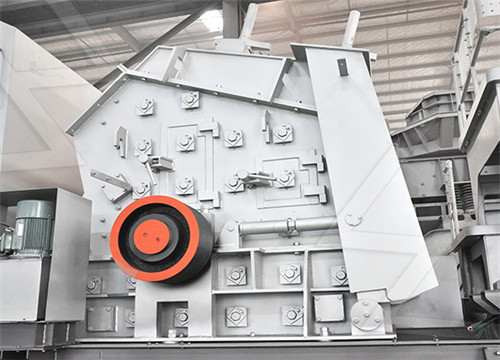

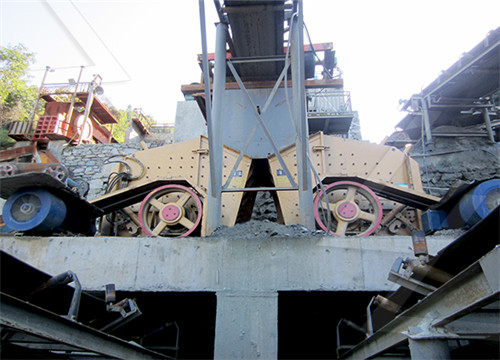

2017-10-25 Jaw crusher usually is primary crusher for ore primary crushing. Impact crusher is also can be used in Copper ore crushing process.Cone Crusher may be the best copper ore crusher processing machine. The next step is screening process. According to the requirements of size, choose the right screening machine to screen out the eligible Copper ore.

2021-5-18 Copper Ore Crushing Production Line, Mobile Crusher Machine for Processing. Crushing is the first stage in copper production operation; it aims to reduce the large lumps of raw materials into small particles.Jaw crusher, impact crusher, cone crusher or gyratory crushers are usually applied in copper crushing.

2022-4-25 Screens size and distribute the classified ore to a series of conveyors, like those above, for transportation to the mill for further processing. 03. After crushing process, the copper ore is send to ball mill for grinding. Inside the ball mill, the crushed copper ore will grind the ore to about 0.2 mm with 3-inch steel balls. 04

2021-5-18 First the copper ore is blasted, the copper ore stone will be loaded by a heavy duty truck, then be transported into the primary crusher which reduces the ores to 8 inches or smaller. Screens size and distribute the classified ore to a series of conveyors, like those above, for transportation to the mill for further processing.

Copper ore primary crushers camelway crusher sulfide ores are beneficiated in flotation cells while the oxide ores are generally leached first the copper ore from a open pit mine is blasted loaded and transported to the primary crushers then the ore is crushed and screened with the fine morenci copper mine arizona mining technology morenci...

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required. Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etc. For minerals with different properties and hardness, we can recommend suitable crusher accordingly

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

2021-11-1 copper crushing flow gold ore process flow diagram primary crushing copper mining extraction process flow chart mineral gold ore mining processing plant diagram ore is stockpiled 1 at the processing plant and the process begins by feeding the ore into a hopper with a loader the ore is conveyed and lime is added 2 to raise the ph of the ore following crushing through a jaw

2022-4-25 Mobile Crushing Station mainly include crawler and wheeled-type crushers. This selection include jaw crushers, impact crushers, cone crushers and screens. Mobile Screening Plant. Mobile Plants. Mobile Crusher. Portable Rock Crusher. Stone Crushing Machine. Ore Processing Equipment. Powder Grinding Mill.

2013-8-5 Copper Ore Processing Copper mining is usually in open copper mines or underground copper mine. First the copper ore is blasting, loading to the primary crusher. In the primary crusher, the ore is broken into small pieces with diameters less than 25cm. And then Crushed ore is loaded on the conveyor belt to storage slot.

2021-5-18 Copper Ore Crushing Production Line, Mobile Crusher Machine for Processing. Crushing is the first stage in copper production operation; it aims to reduce the large lumps of raw materials into small particles.Jaw crusher, impact crusher, cone crusher or gyratory crushers are usually applied in copper crushing.

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required. Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron

Stone Crusher Used For Copper Ore Processing. Applications HJ series jaw crusher is widely used in various materials processing of mining construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral rocks. 247 Online Copper ore beneficiation Stone Crusher used for Ore.

Copper Ore Beneficiation Production Line Stone Crusher. Jan 12, 2016 We usually use copper beneficiation flotation process, the process is as follows: 1, the first original material transported to crushing copper ore zone, into the jaw crusher for primary crushing, then the output material into the secondary crusher, for example cone crusher, get smaller copper ore, and then crushed

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

Copper Ore Processing Luoyang Dahua. According to the normal ore beneficiation process, copper ore processing is divided into crushing grinding grading floating –high grade copper ore tailing disposal. Crushing machine: Normally the ore dressing plant that the crushing scale is above medium . get price

2022-4-25 Mobile Crushing Station mainly include crawler and wheeled-type crushers. This selection include jaw crushers, impact crushers, cone crushers and screens. Mobile Screening Plant. Mobile Plants. Mobile Crusher. Portable Rock Crusher. Stone Crushing Machine. Ore Processing Equipment. Powder Grinding Mill.

Sanme Provides high-quality crushers, jaw crusher, cone crusher, mobile crusher and sand maker as the main product while feeder, belt conveyor and powder separator as the mating equipments.

2021-9-3 The NextGen 2 is demonstrating its capability to process ore with both a low moisture content and with a higher moisture content, such as marra mamba ore. copper and lithium. However, MRL’s innovations also extend to carbon fibre technology. In what it says is a world first, MRL has successfully developed carbon fibre vibrating screens