In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is

Durable Design. The Trio® APP Series horizontal shaft impact crusher comes with solid, one-piece, welded steel rotors with abrasion resistant wear plates, forged steel rotor shafts and monolithic manganese steel primary curtains. This allows the impact crusher to operate in even some of the harshest conditions. Designed for Primary Crushing.

Horizontal Impact Roll Crusher with integrated chain conveyor, large feed size, suitable for sticky materials. True horizontal crushing. PRIMARY HORIZONTAL IMPACT CRUSHER HHI. Model Max. Feed Size [mm] Capacity [t/h] Power Requirements [kW] HHI 1515 : 1,000 x 1,400 : 500 1,800 : 160 500 : HHI 1518 :

MEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration. This helps the crusher to operate safely and boosts productivity. MEKA primary

Feel free to contact us. We are always ready to help you. No. 58 Xinjinqiao Road, Pudong, Shanghai, China; Email:[email protected]; Call us now:0086 13671863359

Simultaneous crushing of different raw material components. Primary crusher options: impact crushers, hammer crushers, sizersimpact roll crushers. Generation of a product ideal as feed material for vertical roller mills and ball mills. Consistent high product quality. Reduction on crusher load through pre-screening by wobbler feeders HRS.

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreas-style impactors. At present, we offer the New Holland-style primary impact breaker and the MaxCap X-Series Primary, providing a

Vertical Shaft Impact Crushers MEKA Vertical Shaft Impact crushers are designed to be used in secondary, tertiary or quaternary stage crushing. These crushers are suitable for a wide range of applications including the production of high-quality manufactured sand, well-formed aggregates and industrial minerals. More Information

2018-12-26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 Primary Crusher The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary (second), tertiary (third) or quaternary (fourth) crushers.

2020-12-17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Stone production line, a stone crushing and sand making process composed of primary crusher and secondary crusher. Crushing operations often divide into coarse crushing, medium crushing and fine crushing according to the size of feeding and discharging granularity. Commonly used crushing equipment includes jaw crusher, cone crusher, impact

Zhengzhou Dingsheng Engineering Technology Co., Ltd. (7) Zibo United Tech Machinery Co., Ltd. (5) Submit. Choosing the right crusher. Impact crushers can be used as primary crushers, secondary crushers or tertiary crushers depending on the size and technology. They are equipped with beaters, also called hammers, and impact plates.

Technical specification of horizontal shaft impactor (HSI Crusher) Horizontal Shaft Impactors (HSI Crusher) are primary and secondary impact crushers. They are available in 20 sizes with rotor dimensions from 12” to 72” and feed .

Leading materials and minerals processing technology provider IMS Engineering (IMS) has replaced a jaw crusher at long-time client, Vaal-based Clinker Supplies, with a AP-PH 1415 primary impact crusher. According to Clinker Supplies’ Karl Pfeffer, apart from the numerous advantages of the primary crusher, one of the principal

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

2020-5-6 There are three types of crushers. Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer

2020-12-17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

HPI-H Primary Crusher. With throughput rates up to 600 t/h, HPI-H Primary Impactors are used extensively in the cement, aggregate and recycling industries. With deflection-free, horizontal material flow, our HHI crushers feature an infeed/discharge chain conveyor arranged below the impact roll.

jaw crusher. PE750×1060. Capacity: 110 t/h 250 t/h. Weight: 27 t. Motor power: 110 kW 150 kW. PE750×1060 jaw crusher is used in the first process of coarse and medium crushing various minerals and rocks. The advantages of high efficiency, strong crushing capacity and low investment cost make jaw crusher

2016-2-17 The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl

Stone production line, a stone crushing and sand making process composed of primary crusher and secondary crusher. Crushing operations often divide into coarse crushing, medium crushing and fine crushing according to the size of feeding and discharging granularity. Commonly used crushing equipment includes jaw crusher, cone crusher, impact

Technical specification of horizontal shaft impactor (HSI Crusher) Horizontal Shaft Impactors (HSI Crusher) are primary and secondary impact crushers. They are available in 20 sizes with rotor dimensions from 12” to 72” and feed .

Zhengzhou Dingsheng Engineering Technology Co., Ltd. (7) Zibo United Tech Machinery Co., Ltd. (5) Submit. Choosing the right crusher. Impact crushers can be used as primary crushers, secondary crushers or tertiary crushers depending on the size and technology. They are equipped with beaters, also called hammers, and impact plates.

primary crusher/stone crusher/ coal crusher Buyer,primary . primary crusher/stone crusher/ coal crusher Place of Origin: Henan, China (Mainland) Brand Name: SINON machinery Model Number: PEX600*900 Type: Cone Crusher.

Horizontal Shaft Impact Crusher. Horizontal Shaft Impact Crushers with adjustable curtains are suitable for crushing medium and hard stones for the production of asphalt, sand and concrete aggregate. THe basic merits of Horizontal Shaft Impactors are: High Tonnage; Low Capital Investment; Cubicle particle shape achieved; High specification

Primary Jaw Crusher (3) 36"X30" (900X750mm) Primary Jaw Crusher; 24"x14" (600x350mm) Jaw Crusher Primary; DT3024 Double Toggle Jaw crusher; Deepa Sand Machine is a Horizontal Shaft Impact (HSI) Crusher, specially designed to produce sand from (-) 40mm size aggregates. Get Best Quote Request A Callback. EXPLORE MORE CATEGORIES.

2022-5-7 ELRUS Horizontal Shaft Impactors. Our horizontal shaft impact (HSI) crushing plants are outfitted with Prisec™ crushers. Sandvik's Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode. Sandvik’s patented design gives you amazing

jaw crusher. PE750×1060. Capacity: 110 t/h 250 t/h. Weight: 27 t. Motor power: 110 kW 150 kW. PE750×1060 jaw crusher is used in the first process of coarse and medium crushing various minerals and rocks. The advantages of high efficiency, strong crushing capacity and low investment cost make jaw crusher

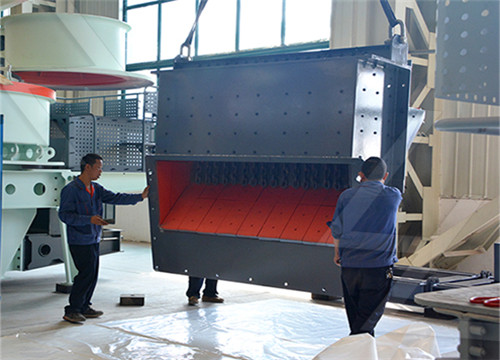

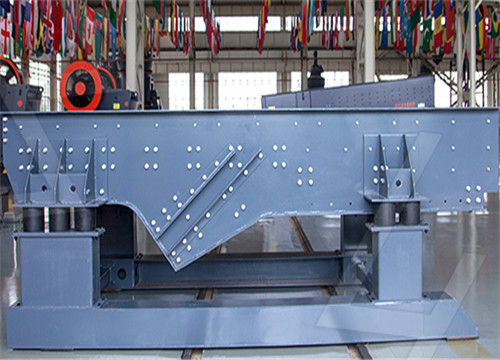

APC STONE CRUSHING EQUIPMENTS. “APC STONE CRUSHING EQUIPMENTS” manufacturers and suppliers of stone crusher stationary as well as mobile plant machineries like Jaw crusher, Horizontal shaft impactor, Vertical shaft impactor, Cone crusher, Sand wash, Vibratory screen, Hopper, Grizzly feeder, Conveyors. Electric control panel for stone