2013-3-9 The process of sintering is basically a pre-treatment process step during iron making for the production of the charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes (collected

The crushed ore is sorted over screens and resized to different specifications, such as lump and fines products. Once the iron ore is processed, a stacker builds a stockpile in the stockyards. In 2020, we produced around 280 million tonnes of iron ore. That's enough to make the steel for more than 3,300 Sydney Harbour Bridges. Our new South

Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel. Expertise. Designed and supplied the

Iron ore fines before and after liquefaction. Shippers must declare the moisture content separately for each cargo hold of the vessel, unless sampling has shown that the moisture content is uniform throughout the entire consignment. 12 In concentrates, the moisture content is often sufficiently uniform, but in unprocessed ores such as iron ore

2016-1-1 The role of chemical reagents to reduce moisture in iron ore fines is explored in the present work which includes ionic and non-ionic surfactants. The washing of iron ore in mineral processing plants result in moisture of about 11–14% in the fines and about 4% in the sized ore. The moisture level goes up to 16% in the fines during the monsoon

2018-7-11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

2020-10-26 The fractions +10mm are considered as the Lump portion of the resource and -10mm fraction is considered as the Fines portion of the resource. Iron ore is of different types observed in hand specimen as well as drill core samples of an iron ore deposit in Jharkhand and Odisha, which are as follows: Hard Laminated; Hard Massive; Soft Lamiated

2020-4-7 TSI Iron Ore Fines 58% Fe 1.5% Al China Imports CFR Qingdao Port TS01047 TSMBX03 Assessment Daily 58% Fe, 9% moisture, 10% loss on ignition, 5.5% silica, 1.5% alumina, 0.05% phosphorus, 0.02% sulfur Granular size of up to 10 mm for up to 90% of cargo min 50,000 mt CFR Qingdao, China 14-56 days forward

2022-5-14 Iron ore is the primary raw material used to make steel. Steel is strong, long-lasting and cost-efficient making it perfect for everything from washing machines to cars, bridges and skyscrapers. According to the World Steel Association, steel is the most commonly used alloy in the world. Global steel consumption is forecast to grow by 1%-2%

Sinter fines and lumps make up the bulk of the seaborne iron ore market, and are the products most frequently traded on a spot basis, so daily pricing is used for the key 62% Fe, 58% Fe and 65% Fe fines, and lump premium references. By contrast, the beneficiated ore segment comprising pellet and concentrate is smaller in terms of both

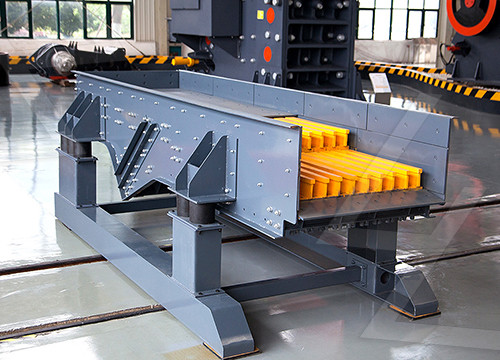

2015-1-1 Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation.As shown in Figure 14.1, iron ore sintering is carried out in three

2021-5-25 Iron Ore Fines. Iron ore fines is found in the form of rocks, mixed with more elements. By means of various industrial methods, it is processed and then supplied. Voltcon International is an established trader of ores in different Location In world. Our extensive stock profile includes Iron Ore Concentrates, Iron Ore Pellets and Iron Ore Lumps.

Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel. Expertise. Designed and supplied the

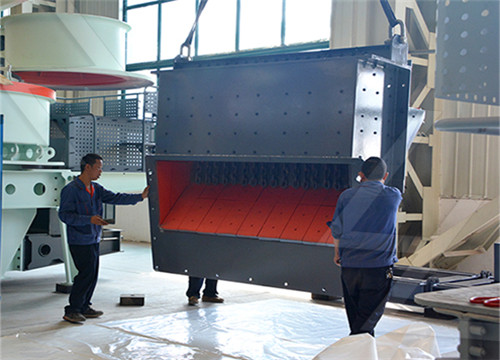

Fines are produced during transportation, handling and storing of iron pellets. The presence of fines can significantly affect the behaviour of iron ore pellets during these processes. In addition, increased volumes of sinter fines are being produced and handled and their behaviour can also be significantly affected. Silos and other equipment

Iron ore fines before and after liquefaction. Shippers must declare the moisture content separately for each cargo hold of the vessel, unless sampling has shown that the moisture content is uniform throughout the entire consignment. 12 In concentrates, the moisture content is often sufficiently uniform, but in unprocessed ores such as iron ore

2019-6-8 High-LOI iron ore fines are required for detailed laboratory pelletization studies and are used in pellet making. The received iron ore is martite–goethitic and hematite–goethitic form of ore with high LOI content. The iron ore consists of 57.7% Fe, 6.19% SiO2, 2.69% Al2O3, 8.80% moisture and 8.85% LOI. From thermo-gravimetric analysis, the

2016-1-1 The role of chemical reagents to reduce moisture in iron ore fines is explored in the present work which includes ionic and non-ionic surfactants. The washing of iron ore in mineral processing plants result in moisture of about 11–14% in the fines and about 4% in the sized ore. The moisture level goes up to 16% in the fines during the monsoon

2020-4-7 TSI Iron Ore Fines 58% Fe 1.5% Al China Imports CFR Qingdao Port TS01047 TSMBX03 Assessment Daily 58% Fe, 9% moisture, 10% loss on ignition, 5.5% silica, 1.5% alumina, 0.05% phosphorus, 0.02% sulfur Granular size of up to 10 mm for up to 90% of cargo min 50,000 mt CFR Qingdao, China 14-56 days forward

2014-5-13 Issues relating to quality control in iron ore production are discussed in [1,2]. When ore is crushed and split into lump and fines components, there are systematic differences between the lump and fines compositions. The lump component is usually (but not always) richer in iron, and with less silica and alumina, than the fines product.

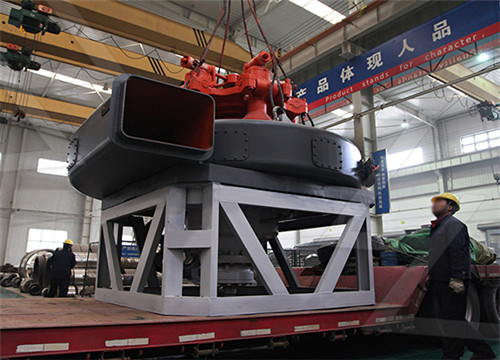

2017-10-6 The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives. — anthracite, dolomite — and

Fines are produced during transportation, handling and storing of iron pellets. The presence of fines can significantly affect the behaviour of iron ore pellets during these processes. In addition, increased volumes of sinter fines are being produced and handled and their behaviour can also be significantly affected. Silos and other equipment

2013-2-23 The various advantages of iron ore pellets are given below. Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore

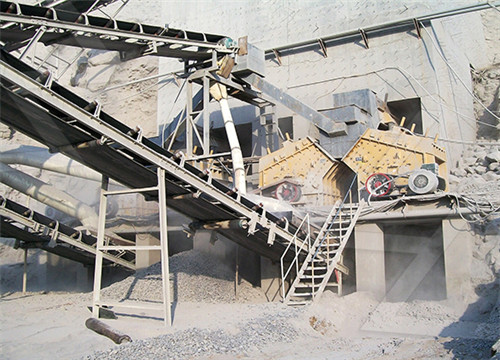

In such a facility, the iron ore fines are mixed with fluxes, carbon fuel, and water. The mixture is continuously fed onto trays or belts. As the conveyor moves through the sintering furnace, the mixture is heated to ignite the fuel and sinter the powder. Reaction waste consists of carbon dioxide, carbon monoxide, as well as nitrous oxides and

2022-4-14 Historically it has provided a direct feed to smelters either as a raw lump or fines, also in a processed form such as sinter or pellets. There are emerging markets for new varieties of feedstock. Its iron ore potential was assessed in the early 1960s at the Razorback Ridge prospect. The average head grade is ~25% Fe. Much of its strike

2016-1-1 The role of chemical reagents to reduce moisture in iron ore fines is explored in the present work which includes ionic and non-ionic surfactants. The washing of iron ore in mineral processing plants result in moisture of about 11–14% in the fines and about 4% in the sized ore. The moisture level goes up to 16% in the fines during the monsoon

2022-4-26 Iron ore fines 62% Fe CFR Futures News. (Bloomberg) -- The northern port of Qinhuangdao is the latest Chinese commodities hub to get hit by virus-related lockdowns. The city in Hebei province has

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. 98% of the mined iron ore is used to make steel.[1] Indeed, it has been argued that iron ore is "more integral to the global economy than any other commodity, except perhaps oil". Iron ore Bulk density ( Kg/m3) 1250 to 3448

India: Bids drop in OMC's iron ore fines auction Fines/Lumps Intel 149 Reads 1 Min 19 May 2022, 15:52 IST. Brazil: Pellets exports rebound 85% m-o-m in Apr'22 Pellets Insight 134 Reads 3 Min 19 May 2022, 15:40 IST. China: Iron ore spot prices fall as Chinese steel margins contract

S. M. Niryat Private Limited Offering Iron Ore Fines, आयरन ओर फाइन्स, New Items in Kolkata, West Bengal. Read about company. Get contact details and address| ID: 9342357797 The iron ore supplied by us forms the major component for the ironsteel and downstream industries. We ensure complete satisfaction of our