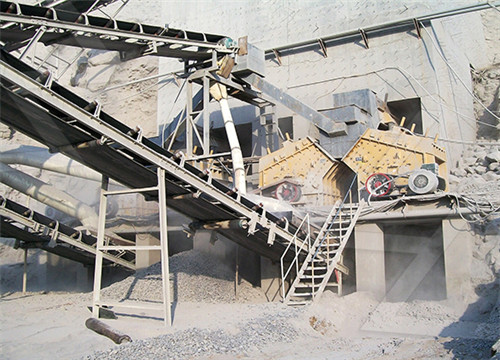

Jaw crusher is one of the most important equipment of the concaveplants. It can be designed in two different ways, mobile and stationary. This type of crusher breaks large stones in crushing and screening plants, bringing them to smaller sizes. Thus, aggregate is obtained from stones. Jaw crusher are very powerful crushers that can be used in

2022-5-13 Striker mobile jaw crushers are known to crush 24/7 in the harsest of mines and quarries. Built to last tested globally and in Australian remote mine sites. Striker mobile jaw crushers are available in a range of sizes and are fitted with world renowned jaw crushers. The single toggle crushing action and design of jaw stock geometry

2021-10-28 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than other kinds of jaw crushers. Why choose Fote jaw crusher manufacturer? The various types of jaw crushers designed by Fote are widely used in many fields including

Presence of primary jaw crusher enables to crush big and hard rocks. On the other hand, thanks to the secondary impact crusher, it is possible to produce good cubical shape of final materials from 0 to 60 mm as per customer needs. CJC-60, CJC-90 and CJC-110 are the primary jaw crusher models which are present on JT-1, JS-2 and JS-3 respectively.

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you

2020-10-9 Jaw crusher is a type of rock crusher. It can be divided into two major types according to its different working principle, Double-toggle jaw crusher and overhead eccentric jaw crusher. Of course, both of the two types of jaw crushers can be used to crush stones. You need to choose the right type when you need to use a jaw crusher.

The MC 140 PRO specializes in high annual mining capacities and large feed sizes. This is helped by the solid double-deck prescreen, which is over three meters long, as well as the powerful diesel engine. The single toggle jaw crusher with its weight of over 50 tons can process feed sizes of up to 1300 x 1000 mm edge length and depending on the

2015-12-23 An in-pit and mobile crusher facilitates the transport of crusher material (ore, stone, rock) out of the mining area via also mobile or portable conveyors. The type of primary crushing is done using any of the several types of crushers available today capable of taking coarse/large rocks: Jaw Crushers.

QJ241 JAW CRUSHER ENGINEERING IN MOTION QJ241 JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm / 40” x 26” Optimum feed size 520 mm3 / 21 inch3 Engine C7.1 Acert 168 kW / 225 hp Transport dimensions 13.90 m / 45’ 7 ⅜” (l) 2.64 m / 8’ 7 ⅞” (w) 3.22 m / 10’ 6 ⅝” (h)

MP-J SERIES MOBILE JAW CRUSHING PLANTS Gongyi Jingying Machinery Manufacturing Factory, Characteristics of MP-J Series Mobile Jaw Crush Contact us on 0086-371-64372138 or jymachine@hotmail Toggle navigation

2022-5-13 Striker mobile jaw crushers are known to crush 24/7 in the harsest of mines and quarries. Built to last tested globally and in Australian remote mine sites. Striker mobile jaw crushers are available in a range of sizes and are fitted with world renowned jaw crushers. The single toggle crushing action and design of jaw stock geometry

2021-10-28 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than other kinds of jaw crushers. Why choose Fote jaw crusher manufacturer? The various types of jaw crushers designed by Fote are widely used in many fields including

Lokotrack ® LT130E™ mobile jaw crusher features the ® C130™ jaw crushing unit, which is designed for crushing hard rock types such as granite, basalt and gneiss. Its d eep 1,000 mm (40”) feed opening can handle coarser feed material and greatly reduces the need for blasting and hammering. A small nip angle and excellent kinematics ensure aggressive crushing along

2022-5-11 With an output size of 3/4″ to 3-1/4″ at a rate of up to 34 tons per hour this machine is perfect for any contractor looking to reduce excavation or construction waste directly onsite. The K-JC503 mobile jaw crusher allows you to directly reutilize crushed material, avoiding transport costs. Stop wasting time and money on excavation and

2020-10-9 Jaw crusher is a type of rock crusher. It can be divided into two major types according to its different working principle, Double-toggle jaw crusher and overhead eccentric jaw crusher. Of course, both of the two types of jaw crushers can be used to crush stones. You need to choose the right type when you need to use a jaw crusher.

2021-11-11 Metso Modular Jaw Crusher 2 (Range: 2540 3042 3055 3648 4248) • The Primary Jaw Crusher module can be fed by a dump truck or by an excavator. Dependant upon the type of feed equipment, the design incorporates different size feed hoppers and size variation on the Vibrating Grizzly Feeders. • Roller bearing Jaw Crusher with motor on a

This jaw crusher is used for high annual production volumes and large feed sizes in natural stone and mining applications. MC 140 PRO Mobile jaw crusher. Diesel-electric. 790 mm x 1,260 mm x 760 mm. 750. t/h. Crusher drive type Electric Crusher inlet (W x D) 1,400 mm x 1,130 mm Crusher weight (approx.) 54,000 kg

2021-9-21 Jaw crusher introduction. Jaw crusher, also named jaw crushing machine or jaw breaker is the world's most ancient form of stone crusher or rock crusher. Jaw crusher's main part is jaw crushing chamber composed of dynamic crusher jaw and static crusher jaw crusher simulating jaw movement of animals to complete the stone material crushing operations.

2015-12-23 An in-pit and mobile crusher facilitates the transport of crusher material (ore, stone, rock) out of the mining area via also mobile or portable conveyors. The type of primary crushing is done using any of the several

QJ241 JAW CRUSHER ENGINEERING IN MOTION QJ241 JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm / 40” x 26” Optimum feed size 520 mm3 / 21 inch3 Engine C7.1 Acert 168 kW / 225 hp Transport dimensions 13.90 m / 45’ 7 ⅜” (l) 2.64 m / 8’ 7 ⅞” (w) 3.22 m / 10’ 6 ⅝” (h)

2022-5-13 Striker mobile jaw crushers are known to crush 24/7 in the harsest of mines and quarries. Built to last tested globally and in Australian remote mine sites. Striker mobile jaw crushers are available in a range of sizes and are fitted with world renowned jaw crushers. The single toggle crushing action and design of jaw stock geometry

Presence of primary jaw crusher enables to crush big and hard rocks. On the other hand, thanks to the secondary impact crusher, it is possible to produce good cubical shape of final materials from 0 to 60 mm as per customer needs. CJC-60, CJC-90 and CJC-110 are the primary jaw crusher models which are present on JT-1, JS-2 and JS-3 respectively.

Lokotrack ® LT130E™ mobile jaw crusher features the ® C130™ jaw crushing unit, which is designed for crushing hard rock types such as granite, basalt and gneiss. Its d eep 1,000 mm (40”) feed opening can handle coarser feed material and greatly reduces the need for blasting and hammering. A small nip angle and excellent kinematics ensure aggressive crushing along

2020-10-9 Jaw crusher is a type of rock crusher. It can be divided into two major types according to its different working principle, Double-toggle jaw crusher and overhead eccentric jaw crusher. Of course, both of the two types of jaw crushers can be used to crush stones. You need to choose the right type when you need to use a jaw crusher.

2021-11-11 Metso Modular Jaw Crusher 2 (Range: 2540 3042 3055 3648 4248) • The Primary Jaw Crusher module can be fed by a dump truck or by an excavator. Dependant upon the type of feed equipment, the design incorporates different size feed hoppers and size variation on the Vibrating Grizzly Feeders. • Roller bearing Jaw Crusher with motor on a

This jaw crusher is used for high annual production volumes and large feed sizes in natural stone and mining applications. MC 140 PRO Mobile jaw crusher. Diesel-electric. 790 mm x 1,260 mm x 760 mm. 750. t/h. Crusher drive type Electric Crusher inlet (W x D) 1,400 mm x 1,130 mm Crusher weight (approx.) 54,000 kg

Jaw crusher Advantages. Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved. Modular design is adopted to save time and installation cost, and minimize on-site construction work.

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

2021-9-21 Jaw crusher introduction. Jaw crusher, also named jaw crushing machine or jaw breaker is the world's most ancient form of stone crusher or rock crusher. Jaw crusher's main part is jaw crushing chamber composed of dynamic crusher jaw and static crusher jaw crusher simulating jaw movement of animals to complete the stone material crushing operations.

2015-7-22 These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its application to the gyratory reduction crusher.