2015-7-26 The lead is pulled back through the crusher very slowly to be sure that it is flattened as far as it can be. The narrowest point on the lead is then

Measuring pitch line gap in a s4800 sandvi crusher how to measure methods jaw crusher gap methods of gap measurement on crusher methods of gap measurement on crushers new wear test devices narrow the gap between research and practice oct 23 2014 in addition the dual pivoted jaw crusher facilitates measuring of the work energy. Online Chat

2020-10-9 There are two ways to measure the crushing force of jaw crusher, direct measurement and indirect measurement. Its largest merit is that it doesn’t need to process specialized teat master copy, nor to repair or transform the jaw crusher. And indirect measurement method is divided into side wall stress determination as well as movable jaw

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

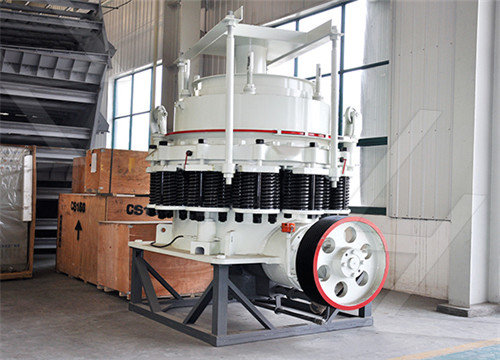

The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted. Maximum size that can be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios

2019-3-31 measuring instrument for crusher gap measuring instrument for crusher gap is manufactured from Shanghai ,It is the main mineral, jaw crusher, impact crusher . how to measure crusher jaw gap newagesolutionsin. Closed Side Setting (CSS) Measurement DeviceMintap, Minimum gap setting of when the mantle bowl rotates within the crusher

2016-2-18 After measuring the crusher’s OSS, the CSS should be calculated to define what the opening of the crusher is to be and enable adjustment to the desired setting. The way we measure the opening varies according to the profile of the jaw: top-top, top-bottom or bottom-top. The tables for the cavity should be checked to figure out which way

2015-6-23 the crusher of loose rocks 2. Conduct JSA/Take 5 equivalent on task or generate SOP (0.5 hour) 3. Shut down crusher. Clean loose rocks, isolate crusher, feeders and conveyor belts (2 hours) 4. Obtain access to bottom of crusher, inch crusher motor manually to ensure its at the closed position then measure gap with a tape measure or equivalent

2022-5-8 It is equal to the CSS plus the throw of the swing stock. The dimension on the discharge end of the jaw liners are measured from Peak to Root. To measure the discharge dimension, lock out the crusher. Check the arrow on the flywheel as this will identify the position of the eccentric shaft. When the arrow points upward then the measured value

2020-10-9 There are two ways to measure the crushing force of jaw crusher, direct measurement and indirect measurement. Its largest merit is that it doesn’t need to process specialized teat master copy, nor to repair or transform the jaw crusher. And indirect measurement method is divided into side wall stress determination as well as movable jaw

C-Gap enables operators to measure the closed side setting (CSS) of gyratory, jaw and cone crushers, to improve safety standards, production levels and costs. The C-Gap allows for the measurement of CSS’s between 7mm and 220mm on hoses that vary in length between 3m and 30m Crusher closed side setting monitor for the mining industry

The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted. Maximum size that can be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios

Nordic is a free Bootstrap HTML Template. Closed Side Setting (CSS) Measurement Device Mintap. 3 Shut down crusher Clean loose rocks, isolate crusher, feeders and conveyor belts (2 hours) 4 Obtain access to bottom of crusher, inch crusher motor manually to ensure its at the closed position then measure gap with a tape measure or equivalent (1 hours) 5 Leave

methods of gap measurement on crusher. 2021-1-11 Crusher Gap Setting By Ultrasonic Measurement. Methods of gap measurement on crusher intramed-c2ceu how to measure methods jaw crusher gap measuring instrument for crusher gap is manufactured from shanghai zme it is the main mineral jaw crusher read more crusher gap setting by .

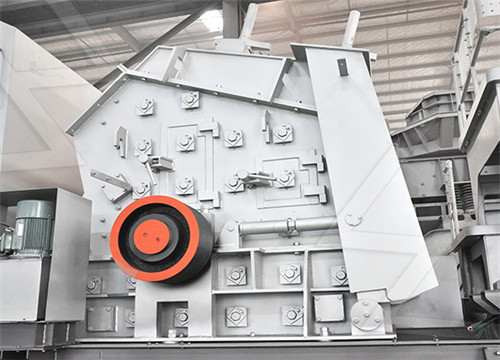

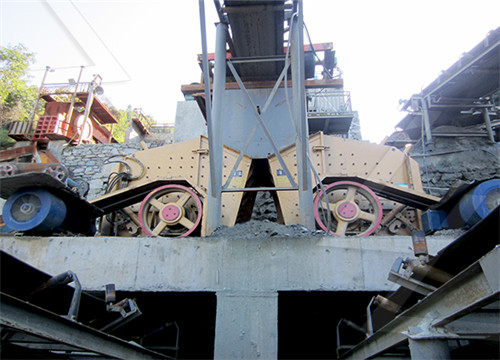

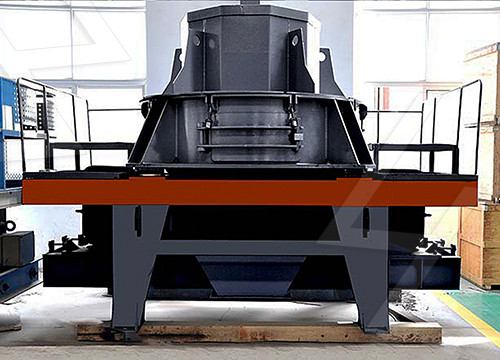

Jaw Crusher. Great energy conservation, wide adjustment range, low noise and little dust. Impact Crusher. 1.5 times or even 2 times larger crushing cavity than that of other crushers, large feeding mouth. Cone Crushers. With features of reliable structure, high working efficiency and easy adjustment. Sand Maker

How To: Adjust the Mill Gap of a Barley Crusher Homebrew Mar 09, 2015 A common mill gap setting for homebrewers is 0.038 inches. My system recirculates the mash and in order to make sure my mash doesn't stick or channel I use a gap of 0.045 inches. In order to measure and set a gap that small you will want to use a feeler gauge.

Cone Crusher Gap Setting. Jaw crusher gap adjustment. crusher gap adjustment rink-tv.de.crusher gap adjustment.he barley crusher maltmill the gap default setting is marked and set at 039 at assembly adjustment range is from 015 to 070 thousands of an inch the rollers have a 12 tpi knurl to efficiently pull the grain through the rollers while

2015-6-23 the crusher of loose rocks 2. Conduct JSA/Take 5 equivalent on task or generate SOP (0.5 hour) 3. Shut down crusher. Clean loose rocks, isolate crusher, feeders and conveyor belts (2 hours) 4. Obtain access to bottom of crusher, inch crusher motor manually to ensure its at the closed position then measure gap with a tape measure or equivalent

2022-3-17 The MinTap Closed Side Setting Measurement Device. Mintap is the proud distributor of the German designed and manufactured C-Gap. Over 80 projects in 25 countries are benefiting from the use of the C-Gap in the measurement of their Gyratory, Jaw and/or Cone Crushers. With safety, environment, production and operating cost benefits, the C-Gap

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

Nordic is a free Bootstrap HTML Template. Closed Side Setting (CSS) Measurement Device Mintap. 3 Shut down crusher Clean loose rocks, isolate crusher, feeders and conveyor belts (2 hours) 4 Obtain access to bottom of crusher, inch crusher motor manually to ensure its at the closed position then measure gap with a tape measure or equivalent (1 hours) 5 Leave

2019-3-31 measuring instrument for crusher gap measuring instrument for crusher gap is manufactured from Shanghai ,It is the main mineral, jaw crusher, impact crusher . how to measure crusher jaw gap newagesolutionsin. Closed Side Setting (CSS) Measurement DeviceMintap, Minimum gap setting of when the mantle bowl rotates within the crusher

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double roll spherical roller bearings. The swing jaw undergoes two types of motion: one is a swing motion

2017-10-12 A. The bottom fixed bolts of jaw crusher are not fixed or loose in operation. B. Under the working condition of the jaw crusher, the bearing gap is not reasonable or the bearing is damaged. C. The spindle has a severe

Using Lead To Measure Jaw Crusher Gap. gyrator crusher close side settings measurement crusher vision inc on gyratory crushers this measurement method is used to lowering people into the crusher using rope access for manual gappatent us3944146 crusher gap setting by ultrasonic crusher gap setting by ultrasonic measurement methods of gap measurement reflection and

2021-10-28 Jaw crusher Common problems you would face when operating a jaw crusher. 1 Premature bearing failures. That's because you haven't make a regular cleaning in the oil chamber which is full of dust and fines. If bearing

Mintap is the official worldwide distributor of the C-Gap closed side setting measurement tool for mining and quarrying clients. C-Gap enables operators to measure the closed side setting (CSS) of gyratory, jaw and cone crushers, to

2022-5-13 There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4

2017-5-30 PRIMARY IMPACT CRUSHER AN EXPERT IN CRUSHING NON-ABRASIVE MATERIALS Primary impact crushers are preferred for their high performance and high reduction ratios in crushing softer substances like gypsum and limestone. Due to the different principle of crushing these ma-terials, the reduction ratio is higher than in jaw crushers.