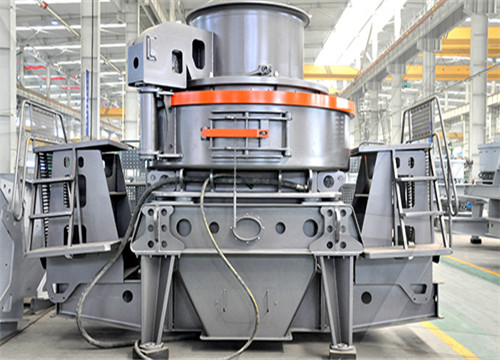

VSI and GS series crushers are characterized by a unique closed-rotor design providing a higher reduction ratio with lower wear cost. The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency.

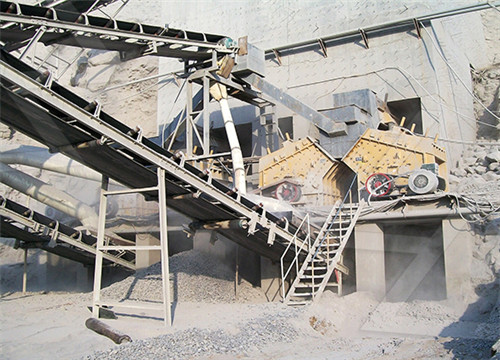

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone

VSI crusher components. Vertical shaft impact crusher consists of feed hopper, distributing system, crushing chamber, rotor assembly, gear, thin oil lubrication system, as well as pedestal. It is through feed hopper that materials go inside vertical shaft impact crusher for sale. Distributing system is above the crushing chamber.

Vertical shaft impact crusher is known as sand making machine, which is an equipment used for sand making and shaping. Our Daswell machinery researches and produces the VSI crusher for a long time. And the equipment absorbs with the advanced technology from Germany, and owned advanced world standards. VSI-7611 crusher. Model. VSI-7611. VSI-8518.

2022-2-18 Vertical shaft impact crusher or VSI uses as an alternative to tertiary impact crushers. VSI applicable in sand quarries, stone quarries, ready-concrete and mining fields. As for tertiary impact crushers the suitable type of hardness is medium like basalt, and hard one as granite for this machinery. The main aim is to obtain 0-5 mm (sand) sizes

2021-10-17 Metso HX series Vertical Shaft Impact Crusher are widely used in crushing nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. It is the indispensable machine in sand making industry and it is also the most ideal truing machine for mining and construction industries.

2015-5-28 VERTICAL SHAFT IMPACT CRUSHER kOLBERG-PIONEER, INC. 700 West 21st Street Yankton, SD 57078 USA 800.542.9311 605.665.9311 F 605.665.8858 JOHNSON CRUSHERS INTERNATIONAL 86470 Franklin Boulevard Eugene, OR 97405 USA 800.314.4656 541.736.1400 F 541.736.1424 kpijci. com

2017-9-1 1. Introduction. Impact crushers have become particularly useful in manufactured aggregates production because of the nature of the breakage mechanisms, which allow direct fragmentation of the particles without leaving residual stress in them (Wills and Finch, 2016).As such, material produced in a particular size range, which may be controlled by the combination

Our family of horizontal shaft impact crushers is ® NP Series™ consisting of 8 different crusher models varying in size and features. These crushers are used in aggregates production, mining operations as well as in recycling applications, normally as stationary crushers. However, some models are also available as mobile or portable

2019-12-10 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone

2022-2-18 Vertical shaft impact crusher or VSI uses as an alternative to tertiary impact crushers. VSI applicable in sand quarries, stone quarries, ready-concrete and mining fields. As for tertiary impact crushers the suitable type of hardness is medium like basalt, and hard one as granite for this machinery. The main aim is to obtain 0-5 mm (sand) sizes

2022-3-2 Nesans CF Series Vertical Shaft Impact crushers combine robust design features and high performance with low operating and maintenance costs. Most noteworthy of CF Series VSI is that they feature Rock on Rock Crushing (RoR) technology, Nesans VSI’s can replicate the process of natural sand formation to the extent where technology has reached till date.

2017-9-1 1. Introduction. Impact crushers have become particularly useful in manufactured aggregates production because of the nature of the breakage mechanisms, which allow direct fragmentation of the particles without leaving residual stress in them (Wills and Finch, 2016).As such, material produced in a particular size range, which may be controlled by the combination

Spokane Model 74 Vertical Shaft Impact Crusher with Stand 121058. Manufacturer: Unknown. Spokane model 74 vertical shaft impact crusher with stand and 250hp electric motor. Has 4-shoe table and anvil ring with good shoes and near new anvils.

2022-5-8 Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI). While the ultimate design of each type of impactor is to crush rock, their methodologies differ. Raw materials: Granite, basalt, limestone, shale, river stone, cement clinker, quartz stone, phosphate ore, bauxite, slag. Capacity: 10-1400t/h.

Vertical shaft impact (VSI) crushers are usually used i n tertiary crushing station of both aggregat e and mining industries for cru shing of ha rd rock mater ial or ores when a product m aterial

Vertical Shaft Impact Crushers MEKA Vertical Shaft Impact crushers are designed to be used in secondary, tertiary or quaternary stage crushing. These crushers are suitable for a wide range of applications including the production of high-quality manufactured sand, well-formed aggregates and industrial minerals. More Information

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

2019-12-10 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Baroda Iron Vertical Shaft Impact Crusher is an excellent choice especially when output and productivity demands are stringent. In quarry, mineral, mining and aggregate sectors, Baroda Iron VSI impact crusher is used for Production of high-quality sand and shaped aggregate. Due to greater versatility of this equipment, it is well established in

2019-3-6 The Vertical Shaft Impactors or VSI Crusher are one type of impact crushers, which offer higher reduction ratios at a lower energy consumption. These impactors. can be considered as a ‘stone pump’ operating like a

2015-5-28 VERTICAL SHAFT IMPACT CRUSHER kOLBERG-PIONEER, INC. 700 West 21st Street Yankton, SD 57078 USA 800.542.9311 605.665.9311 F 605.665.8858 JOHNSON CRUSHERS INTERNATIONAL 86470 Franklin Boulevard Eugene, OR 97405 USA 800.314.4656 541.736.1400 F 541.736.1424 kpijci. com

Spokane Model 74 Vertical Shaft Impact Crusher with Stand 121058. Manufacturer: Unknown. Spokane model 74 vertical shaft impact crusher with stand and 250hp electric motor. Has 4-shoe table and anvil ring with good shoes and near new anvils.

2022-5-8 Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI). While the ultimate design of each type of impactor is to crush rock, their methodologies differ. Raw materials: Granite,

2022-5-5 Two types of impactors are the vertical shaft and horizontal impact crushers. Horizontal shaft impactor (HSI) crushed stone by impacted stone with hammers that fasten to the spinning rotor. Vertical shaft impactor (VSI) makes

VSI Benefits. When it comes to producing materials such as aggregate for road making, VSI crushers use a high-speed rotor and anvils for impact crushing rather than compression force for the energy needed for size reduction. In a VSI, material is accelerated by centrifugal force by a rotor against the outer anvil ring, it then fractures and breaks along natural faults throughout

The use of vertical shaft impact (VSI) crushers is one possible solution, since VSI crushers can create particles with a good aspect ratio and smooth surfaces for use in different applications

Metso VSI Vertical Impact Crusher Vertical Shaft Impact Crusher:::Metso Barmac VSI How it works (English) YouTube:::Metso Barmac VSI Crushers Barmac B-Series VSI:::Metso VSI Crushers 8848 Webs:::Metso Barmac® B Series™ impact crushers Metso Outotec:::Metso VSI Crusher Animation Metso’s Barmac VSI Orange :::Metso Barmac® B Series™

vertical impact crusher structure Vertical Shaft Impact Crushers Apollo Maschinenbau Apollo Vertical Shaft Impact Crusher is widely applied at mining, quarry and sand The optimized rotor structure extends liner life, minimizes In-rotor build-up [randpic] Load and wear experimen Lunar vertical-shaft mining system This report proposes a